New brackets allow Murrplastik cable drag chains to do even more

This latest development means cable drag chain systems from Murrplastik Systemtechnik GmbH can now do more than just connect a power, hydrau-lic oil, air, water, gas or steam supply to mobile equipment.

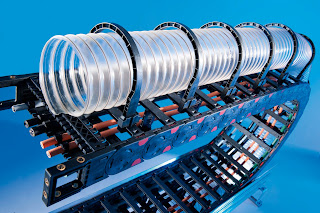

Cable drag chain systems made by Murrplastik Systemtechnik, Oppenweiler (nr. Stuttgart) are a smart solution: they supply mobile equipment with both power and data. Without an “umbilical cord” of this kind – which routes and protects the embedded, flexible cables or pneumatic/hydraulic hoses and ensures that the smallest possible bending radius can be maintained – the equipment’s supply lines would be rendered unusable in no time at all.

Thanks to the innovative skills of engineers at Murrplastik, the impressive utility of the Swabian-produced cable drag chains can now be improved still further. The basic idea couldn’t be simpler: instead of using the chain only on the equipment’s supply side, enhance the system so that it can also be used for waste ducting. Often, such enhancements use tubing made from many kinds of materials, for the suction removal of airborne particulates or welding gas at the workplace. In woodworking, too, waste – chippings and sawdust – very often needs removal by suction. Thanks to the existing modular system, it is now very simple to ensure the safe routing of this kind of suction tubing by using the new Murrplastik brackets attached to the PowerLine range of cable drag chains.

The brackets for suction tubing are either mounted on the frame bridges or (for closed chains) on the plastic or aluminium covers. With open chains, the brackets snap onto the frame bridges. If the chains are equipped with closed covers, then the brackets are bolted onto the covers. Tubing can be attached to the inside or outside bend of the chain. No modifications are made to the chains themselves. Accordingly, the standard shelving systems continue to be usable within the chain: these maintain the proper position of the various services, ensuring lines can move freely but not become twisted. If an application already has cable drag chains installed, then it is also very simple to retrofit the brackets to the system. If a piece of tubing needs replacing, the bracket can be removed and re-attached without difficulty and without needing to open up the chain. Since many different diameters of tubing are available, brackets can of course be supplied in several sizes.

Standard guide channel systems (VAW) from Murrplastik can be used to route the chains. We can supply matching adapters for this scenario, ensuring that the chain and brackets have sufficient clearance.

Cable drag chain systems made by Murrplastik Systemtechnik, Oppenweiler (nr. Stuttgart) are a smart solution: they supply mobile equipment with both power and data. Without an “umbilical cord” of this kind – which routes and protects the embedded, flexible cables or pneumatic/hydraulic hoses and ensures that the smallest possible bending radius can be maintained – the equipment’s supply lines would be rendered unusable in no time at all.

Thanks to the innovative skills of engineers at Murrplastik, the impressive utility of the Swabian-produced cable drag chains can now be improved still further. The basic idea couldn’t be simpler: instead of using the chain only on the equipment’s supply side, enhance the system so that it can also be used for waste ducting. Often, such enhancements use tubing made from many kinds of materials, for the suction removal of airborne particulates or welding gas at the workplace. In woodworking, too, waste – chippings and sawdust – very often needs removal by suction. Thanks to the existing modular system, it is now very simple to ensure the safe routing of this kind of suction tubing by using the new Murrplastik brackets attached to the PowerLine range of cable drag chains.

The brackets for suction tubing are either mounted on the frame bridges or (for closed chains) on the plastic or aluminium covers. With open chains, the brackets snap onto the frame bridges. If the chains are equipped with closed covers, then the brackets are bolted onto the covers. Tubing can be attached to the inside or outside bend of the chain. No modifications are made to the chains themselves. Accordingly, the standard shelving systems continue to be usable within the chain: these maintain the proper position of the various services, ensuring lines can move freely but not become twisted. If an application already has cable drag chains installed, then it is also very simple to retrofit the brackets to the system. If a piece of tubing needs replacing, the bracket can be removed and re-attached without difficulty and without needing to open up the chain. Since many different diameters of tubing are available, brackets can of course be supplied in several sizes.

Standard guide channel systems (VAW) from Murrplastik can be used to route the chains. We can supply matching adapters for this scenario, ensuring that the chain and brackets have sufficient clearance.

Comments