New nozzle allows for faster digging with less water

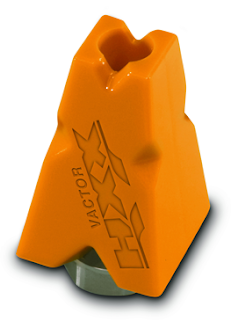

Vactor Manufacturing, the industry leader in vacuum excavators, sewer and catch basin cleaners and industrial vacuum loaders featuring innovative technology and custom configurable designs, today introduced the HXXpose™ nozzle for increased productivity and operator safety in typical hydro excavation applications. The nozzle works with Vactor’s line of vacuum excavators, as well as all other makes and models of vacuum excavation trucks. The rotating water jet agitates a larger area of soil with the same amount of water as a straight jet nozzle for higher efficiency, blasting a 0-degree stream of water rated for pressures up to 3,200 psi, while rotating at a high speed to provide an 18-degree cone of coverage.

“At Vactor Manufacturing, we are committed to continuous improvements of our products so we can deliver the best possible performance solutions to our customers,” said Ben Schmitt, product manager at Vactor Manufacturing. “The heavy-duty HXXpose nozzle, which is standard on all Vactor vacuum excavators, addresses our customers’ growing demand for increased productivity for their hydro excavation projects. This smaller nozzle provides the same productivity as similar, higher water-flow nozzles, while using less water. This allows the operator to remain on the job longer and complete the project with less mess and less downtime to refill the water tank.”

The rugged HXXpose nozzle features high-wear resistant, tungsten carbide internals and a ½-inch, corrosion-resistant FNPT stainless steel casing to hold up against the harshest environments and conditions. The nozzle’s urethane outer coating protects the operator and underground utilities on the site from electrical conduction. The HXXpose nozzle also features a minimum inlet pressure of 1,000 PSI (69 bar) and a maximum water temperature of 180 degrees F (82 degrees C). For extended life and lower operating costs, rebuild kits are available.

“At Vactor Manufacturing, we are committed to continuous improvements of our products so we can deliver the best possible performance solutions to our customers,” said Ben Schmitt, product manager at Vactor Manufacturing. “The heavy-duty HXXpose nozzle, which is standard on all Vactor vacuum excavators, addresses our customers’ growing demand for increased productivity for their hydro excavation projects. This smaller nozzle provides the same productivity as similar, higher water-flow nozzles, while using less water. This allows the operator to remain on the job longer and complete the project with less mess and less downtime to refill the water tank.”

The rugged HXXpose nozzle features high-wear resistant, tungsten carbide internals and a ½-inch, corrosion-resistant FNPT stainless steel casing to hold up against the harshest environments and conditions. The nozzle’s urethane outer coating protects the operator and underground utilities on the site from electrical conduction. The HXXpose nozzle also features a minimum inlet pressure of 1,000 PSI (69 bar) and a maximum water temperature of 180 degrees F (82 degrees C). For extended life and lower operating costs, rebuild kits are available.

Comments